HOW KIGASALI COFFEE IS MADE

Other links

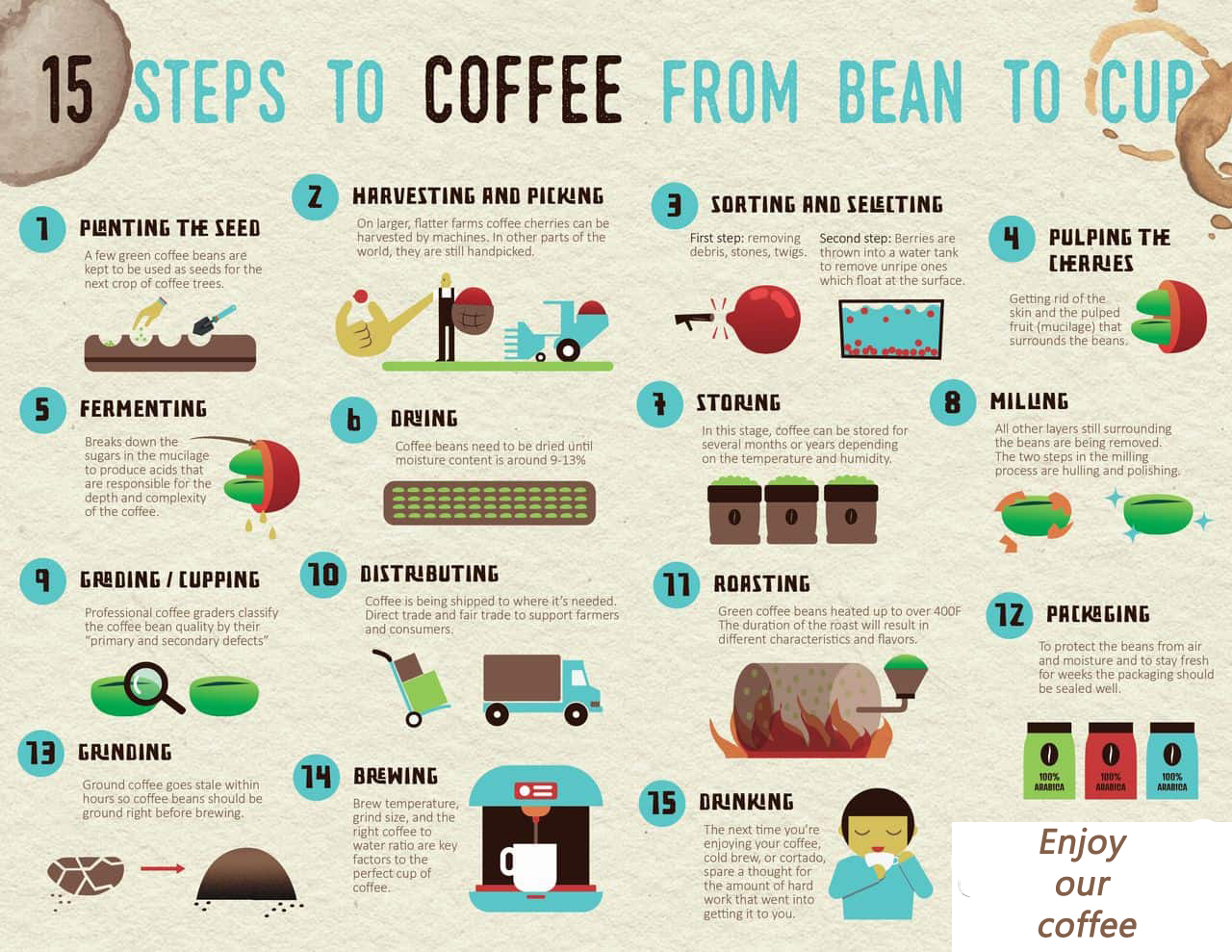

Getting Kigasali coffee has following steps:

Coffee Planting

The first place we need to have is the Nursery in which coffee plants get their roots before

transfered to the farms

Coffee Harvesting

Once the plants start to grow, after a few years, they’ll bear fruit. We’ll get something that looks

like a cherry, with a dark red color that’s ready to be harvested.

Cherries are generally picked by hand where only the really ripe cherries are picked.

Cherries that are picked have to be processed either by a dry method where they are spread out to

dry in the sun or a wet method, where they are skinned and pulped to get the beans out just right.

We used a lot Washed method to get Fully washed green beans

Coffee Milling Process

The beans have to be hulled, polished, graded and more to be prepared for the market. The hulling

process consists of getting rid of all of the exterior parts of the coffee bean.

Exporting the Beans

Green coffee beans are stocked to our warehouse situated at Masaka Industrial zone before selling it locally or being exported

to the world .

Tasting and Grading the Coffee

Green coffee beans are then roasted and tasted to make sure they meet certain quality standards.

They have to be rated on factors like taste, aroma, color and appearance.

Our roasted coffee is branded as IZIMANO coffee

Grinding and Brewing

Once the coffee has been roasted it’s ready to be ground and brewed.

If you prefer to buy

pre-roasted beans or roasted whole beans you can grind your own coffee and then brew it to your preference.